Our Capabilities

Your RTX Solution

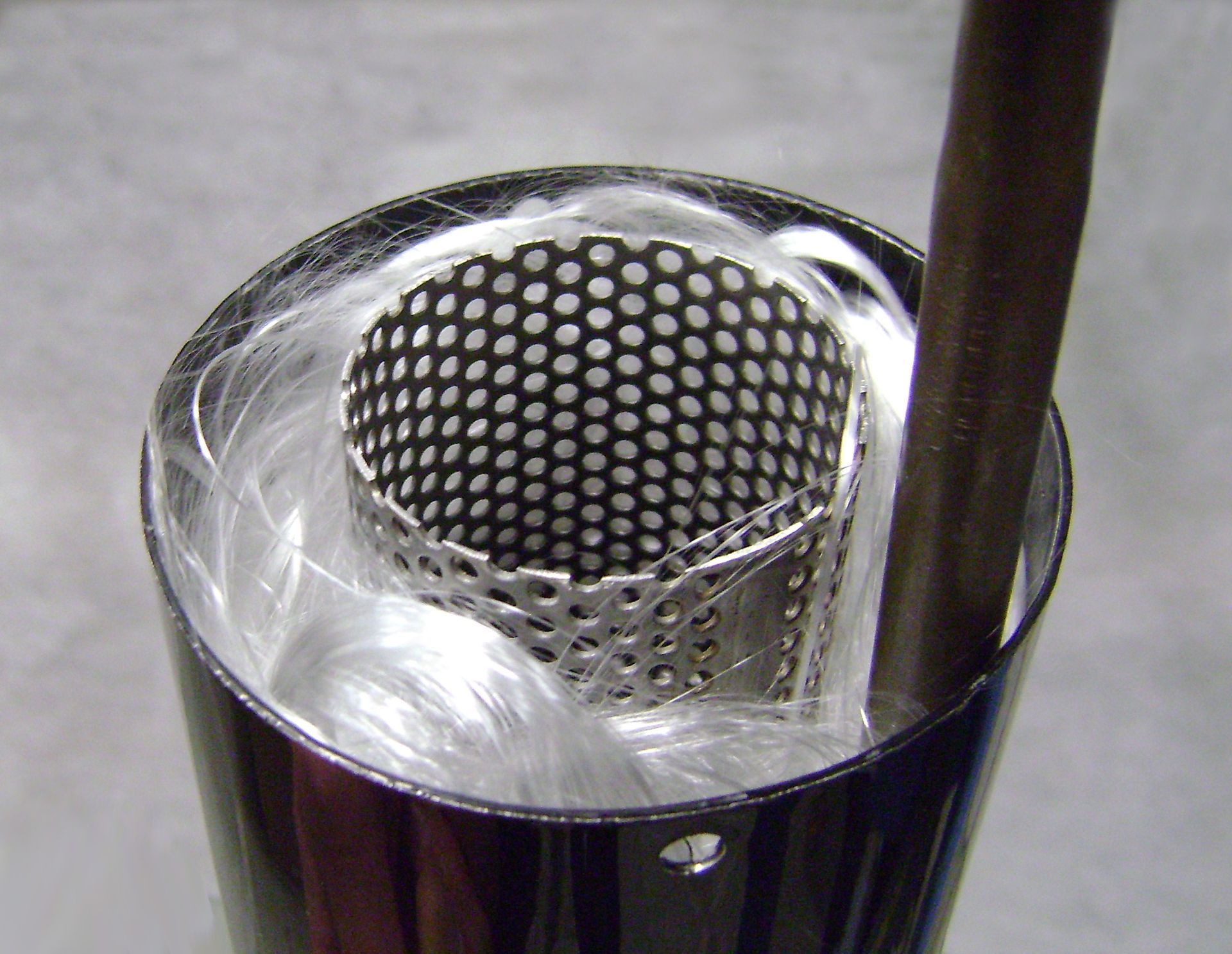

BCI RaceTEX develops and manufactures thermal and acoustical management solutions used in direct flow muffler and silencer exhaust systems for high performance vehicles and industrial equipment. Using highest quality, high temperature fibrous materials with our in-house proprietary manufacturing process, each of these insulation products are custom designed, with select materials and product forms to meet the specific application requirements, complex unit configurations and optimal installation method to maximize the performance and functional durability of the system.

Made in-USA

European designed absorption mufflers were historically know to be the best in the world as the most durable and highest performing. The regulatory requirements were also the most strict. North American manufacturers of high end OEM and aftermarket exhaust systems have learned to meet and even out perform these imported systems, but were forced to import packing materials driving up their cost.

With BCI RaceTEX Products, North American manufactures now have a domestic source for these high performance thermal acoustical insulation packing materials.

Fiber Processing

RaceTEX products are manufactured from the highest quality high temperature continuous filaments fiber available globally. These fibers are then bundled together, volumized and texturized in our in-house fiber processing to optimize the thermal acoustical properties while maintain the strength and durability properties critical to the application. Custom blending of fibers with different chemistries can enhance performance and durability.

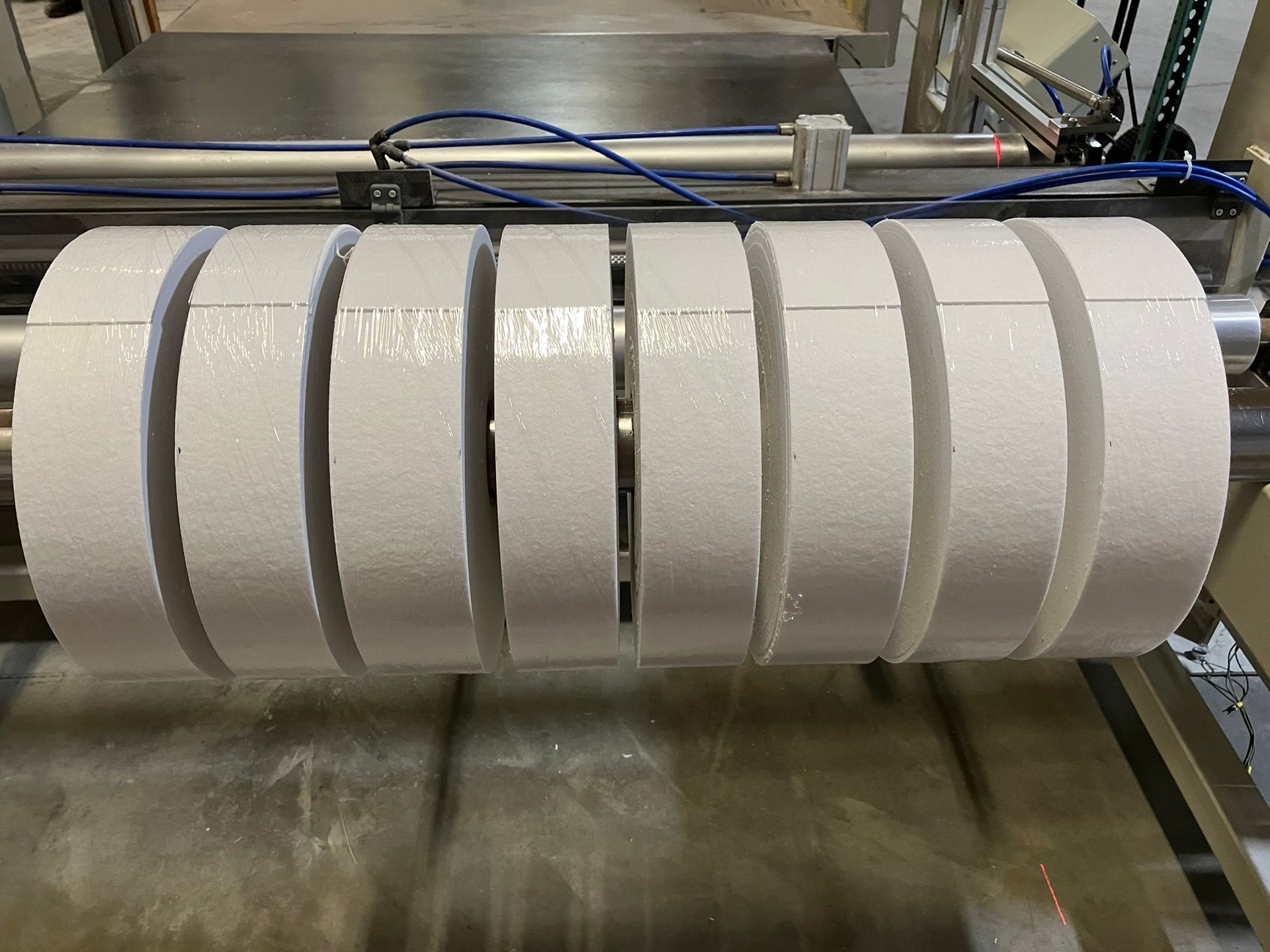

Textile and Non-woven Converting

BCI in-house textile and non-woven capabilities include slitting, die cutting, sewing and lamination, optimized for high temperature fibrous materials including fiberglass, ceramic fiber and stainless steel.

Auto-Filling

Our in-house, proprietary fiber filling processes provide highly efficient pillow and pre-form production using many types of continuous fibers. Direct toll filling capability for custom exhaust manufactures is also provided.

Non-Woven Mat Production

BCI has two unique, proprietary processes to manufacture our non-woven mat products. These mats, contain no organic binders, use fiber entanglement of high temperature continuous filaments strands to provide a novel X-Y-Z fiber orientation. Needle punching and quilting create a strong uniform non-woven in a variety of fiber chemistries and blends, densities, thicknesses and widths.

Preforms and Custom Fabrication

BCI is a fully integrated manufacturer of thermal acoustical insulation packing for high performance exhaust systems. Preforms and custom fabricated parts fit specifically into your exhaust system design, saving installation time ensuring consistent high quality fit and function.

Design & Testing

BCI RaceTEX develops and manufactures thermal and acoustical management solutions used in direct flow muffler and silencer exhaust systems for high performance vehicles and industrial equipment. Using highest quality, high temperature fibrous materials with our in-house proprietary manufacturing process, each of these insulation products are custom designed, with select materials and product forms to meet the specific application requirements, complex unit configurations and optimal installation method to maximize the performance and functional durability of the system.