New Paragraph

New Paragraph

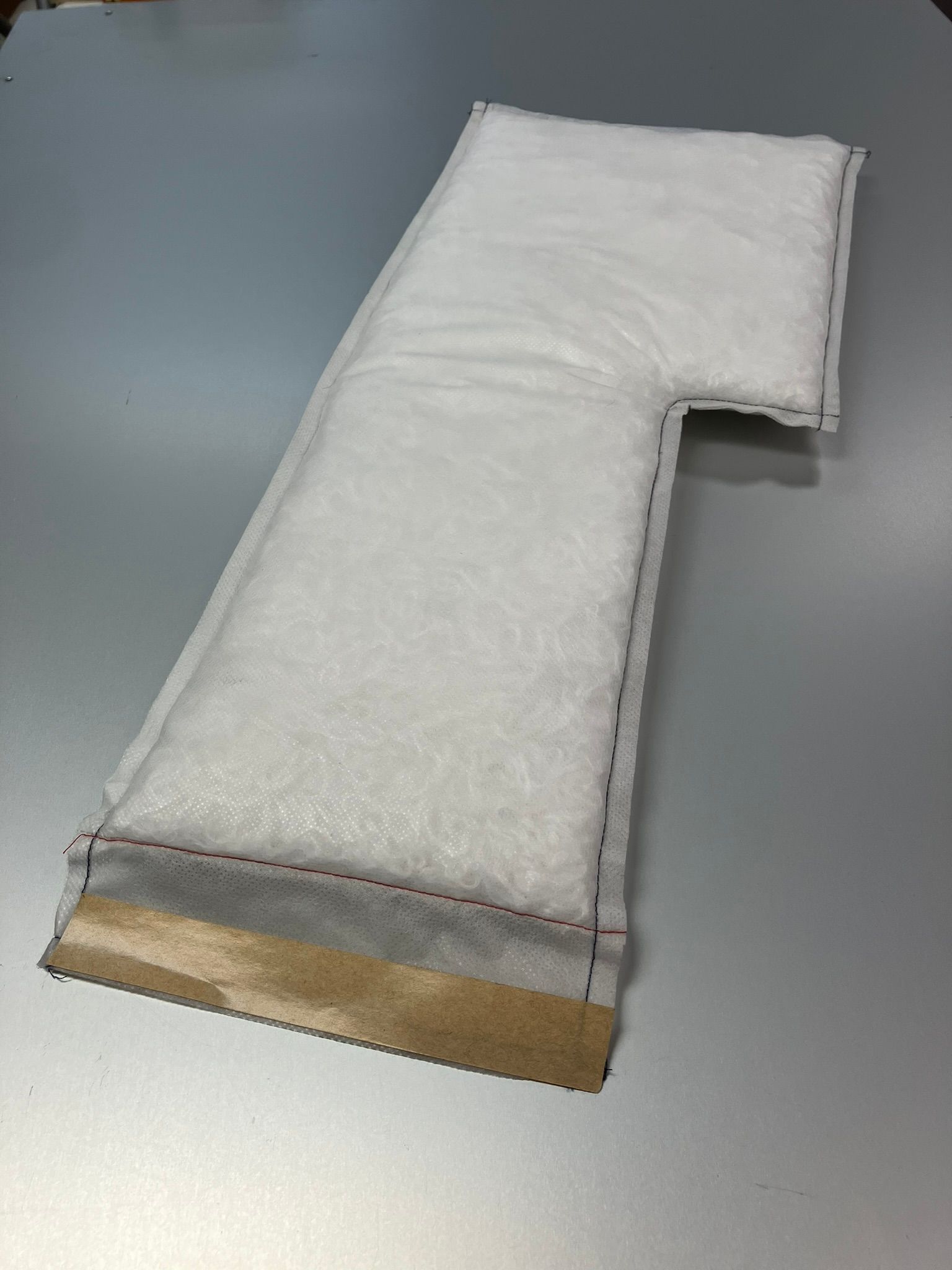

RTX Pillow Encapsulated Fiber Products

Texturized and volumized continuous filament high temperature fibers encapsulated in a textile covering.

Describe some quality or feature of the company. Write a short paragraph about it and choose an appropriate icon.

Short title

Product Differentiators

RTX Pillow Products are filled with a single strand of continuous

filament fiber vs short, chopped loose fibers used in competitive pillow packs. Filling is done with custom designed automated equipment with precise volume control for a consistently uniform part.

Product Overview

RTX Pillow Packing Products are custom designed to the exact dimensions, thickness and densities for your specific muffler. These pillow type packing products are manufactured from any one of the RaceTEX FilFibers required to meet the thermal requirements of that system. These sewn pillow cases are filled to a highly controlled density to provide the desired sound and heat insulation, They are easy to install with a precision fit critical to the durability and performance of the muffler.

Key Features & Benefits

SDS (Safety Data Sheets)

- Pillow Encapsulation provides dust free, ease of installation

- Filling fiber from a single stand of continuous textured filament fiber vs short chopped loose fibers

- Custom designed parts and automated controlled filling ensure proper fit and function.

Pillow Design Options

| Fill Material | Density | Encapsulation Material | Finishing | Shapes |

|---|---|---|---|---|

| Texturized E-Glass | 160-250+ grams per packable liter | Non-woven polypropylene | Quilting | Flat |

| Texturized ECR | 160-250+ grams per packable liter | Woven glass | Double sided-tape | Tubular |

| Texturized Basalt | 160-250+ grams per packable liter | Scrim | Pre-rolled or flat | Tapering / Conical |

| Texturized S-Glass | 160-250+ grams per packable liter | Polyelofin | Heat shrink film | Special Shapes |

| Volumized ECR | 100-250 + grams per packable liter | Labeling / Branding | ||

| Volumized S Glass | 100-250 + grams per packable liter |